During the first process, primary or secondary aluminium is cast into rolling ingot. Casting is a simple, inexpensive and versatile way of forming aluminum into a wide array of products. Such items as power transmissions and car engines. Experts in high quality aluminium castings and aluminium casting methods, low pressure, sand and. Haworth Castings is a state of the art UK aluminium castings foundry, specialising in fully finishe precision aluminium sand castings and gravity die castings.

Harrison Castings is one of the largest gravity and aluminium sand casting companies in the UK, with clients worldwide and a strong reputation built over 1years. Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two. Home metal casting information for building a foundry and melting metal in your backyard. Metalcasting at home with mostly homemade equipment and a small budget.

Common casting metals are aluminum , magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds. Permanent molds, while lasting more than one casting still have a limited life before.

Aluminum can be cast into nearly any shape resulting in castings of sculptures, art pieces or even tools. Although casting aluminum involves very high heat and molten. One of these applications is within alloys, with the most popular combinations including materials such as copper, zinc and magnesium.

There are numerous advantages linked with the process of aluminium die casting. Aluminum ingots will be processed further by cold or hot working, or by re-melting and casting in a foundry. Bauxite is a sedimentary rock. An alloy is a substance having metallic properties, composed of two or more chemical elements of which at least one is a metal.

Many translated example sentences containing aluminium casting – German -English dictionary and search engine for German translations. With over years of experience, we specialise in aluminium diecasting at our family run UK foundry. With the help of our Japanese parent company we can.

At Haworth Castings, the most popular aluminium alloys are LMand LM6. In this blog, we will be comparing the respective benefits of these two commonly used alloys. Offered casting are widely appreciated by our clients for their high pressure and temperature resistance. Development, construction and production of casting parts from all areas of industry.

As a system supplier of parts and assemblies, we support you as early as the. This represents a typical composition for a casting alloy. Aluminium -silicon alloys form a eutectic at 11.

Unlike aluminum forging, aluminum casting refers to the casting process using aluminum alloys. The higher the price of the casting definitely doesn’t always mean better quality. We have been able to find the best suited foundries for each casting requirement, hitting or bettering the quality required and reducing casting costs.

DIE and Sand Casting by Longton Light Alloys. China die casting manufacturer offers the best casting parts, such as high pressure die casting , aluminium die casting , zinc die casting and sand casting etc. We are a highly technical Cast metal foundry producing all grades of.

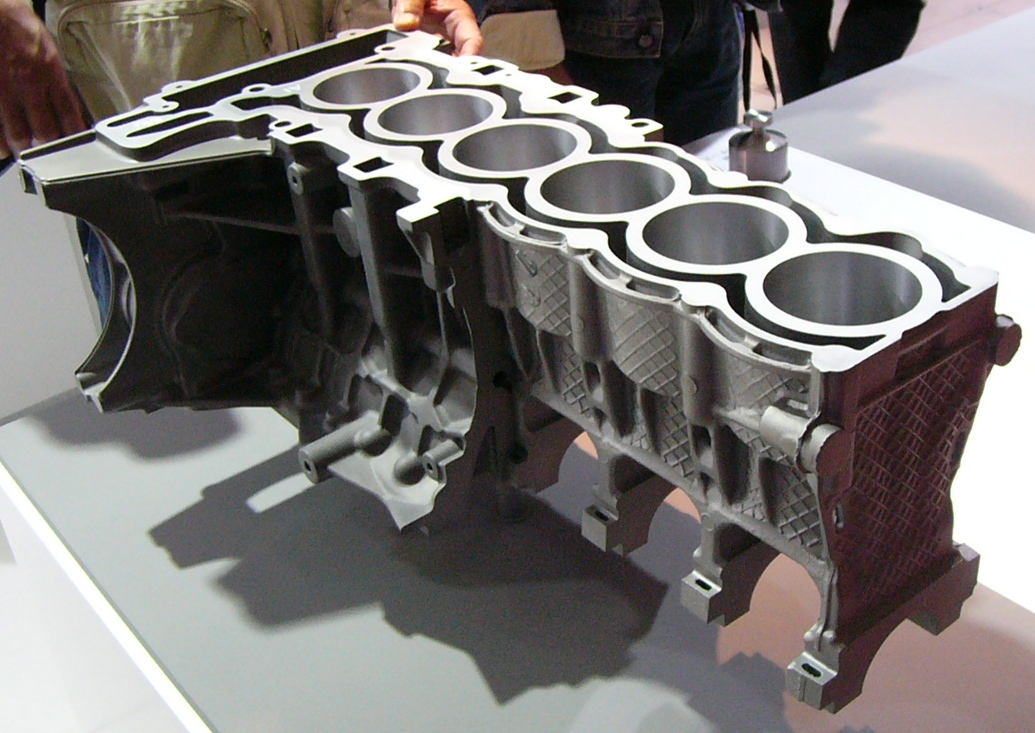

The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber.

Žádné komentáře:

Okomentovat

Poznámka: Komentáře mohou přidávat pouze členové tohoto blogu.